Industrial Sludge Drying Equipment

Industrial Sludge Drying Equipment

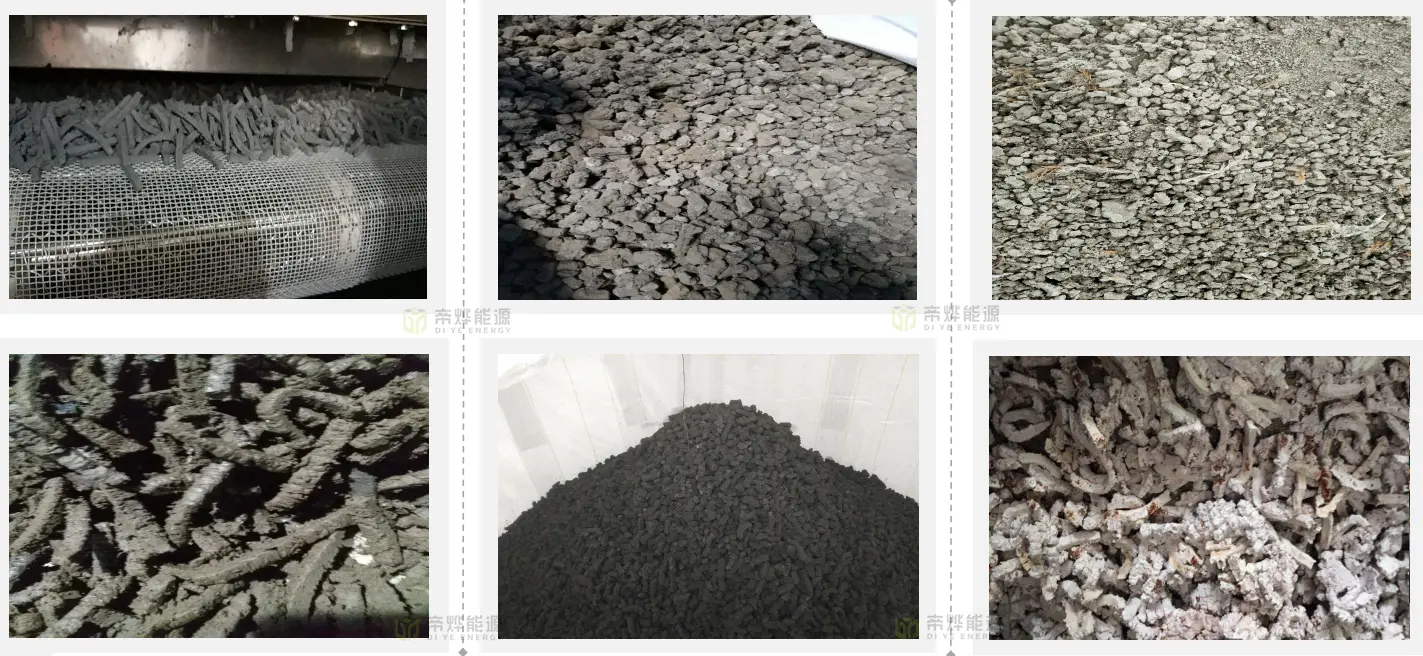

Advantages of Low Temperature Drying Equipment The moisture content of sludge can drop from 80% to 10%-30% after drying process,and the reduction can be as high as 80%. The effective sterilization can be as high as 90%, with low energy consumption and no

Share to:

The moisture content of sludge can drop from 80% to 10%-30% after drying process,and the reduction can be as high as 80%. The effective sterilization can be as high as 90%, with low energy consumption and no pollution.

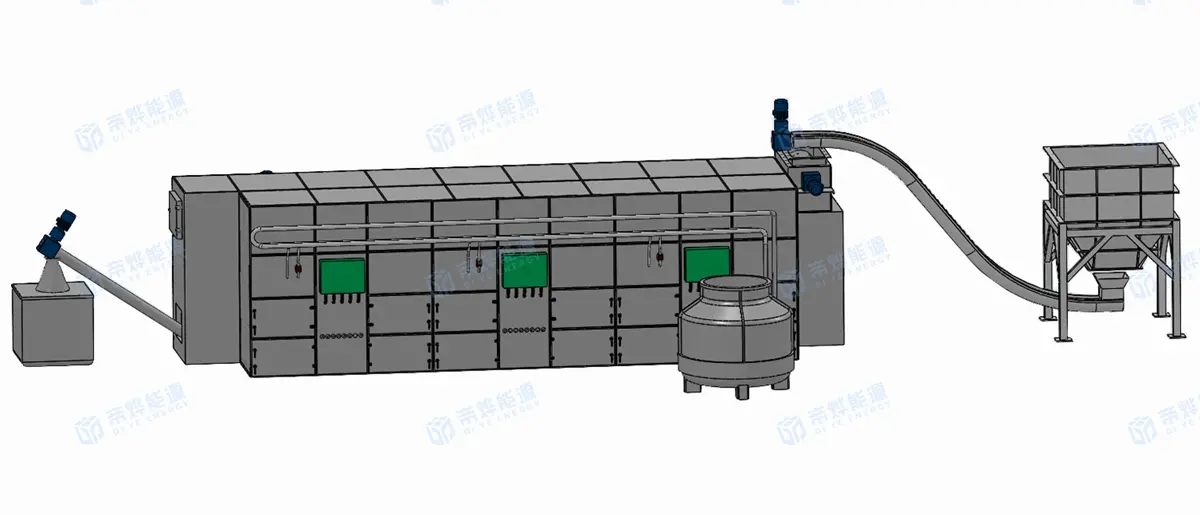

High Automation

Continuous automatic operation of sludge drying is achieved due to the design of the equipment. The sludge drying process avoids the investment of manpower and reduces costs.

Energy saving and eco-friendly,no secondary pollution

The entire equipment system adopts a closed design and heat recovery technology; No heat loss, 100% heat utilization; The moisture is finally discharged in the form of condensate water and the air is recycled; There is no secondary pollution problem of exhaust gas emissions.

Low energy consumption

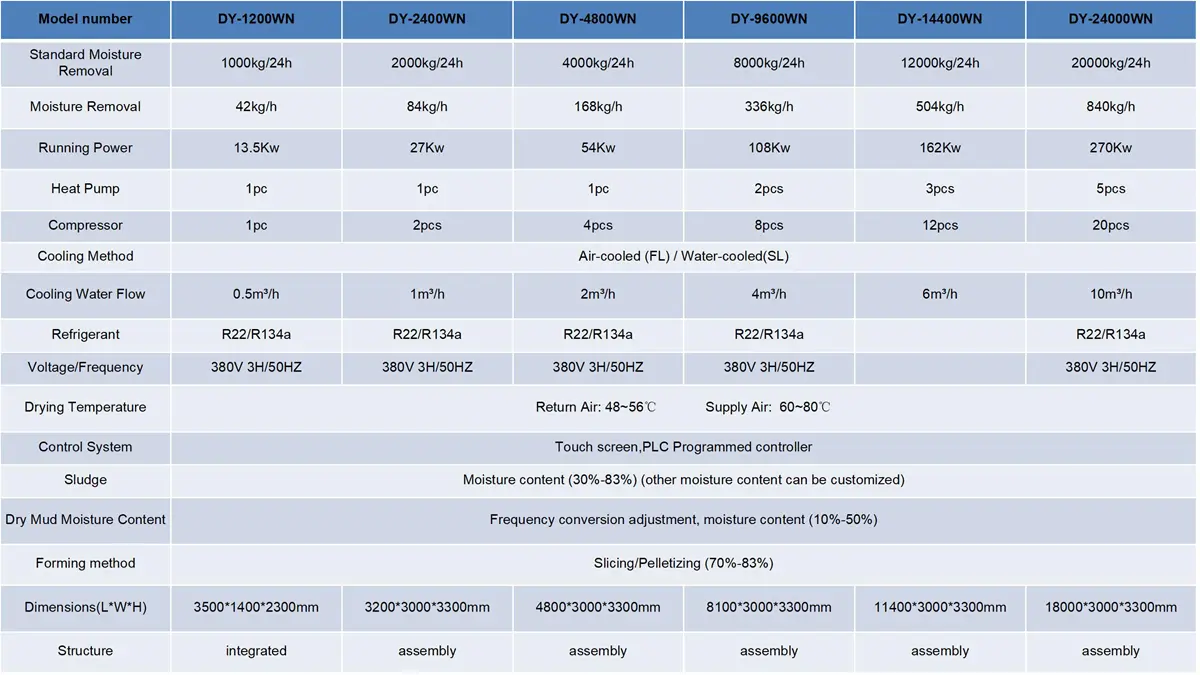

The low-temperature heat pump drying equipment can dry wet sludge with a moisture content of 80% per ton to 30%, and the operating cost is as low as 13.5kw/h.

Low drying temperature,less safety risks

The drying temperature is lower than 70℃, there are few problems such as explosion and toxicity of the sludge that may volatilize; Stable operation and high utilization rate.

Municipal sludge;

Sludge from domestic wastewater treatment;

Industrial sludge(printing and dyeing,paper making,electric plating,chemical industry,leather industry,pharmaceutical industry,etc) .