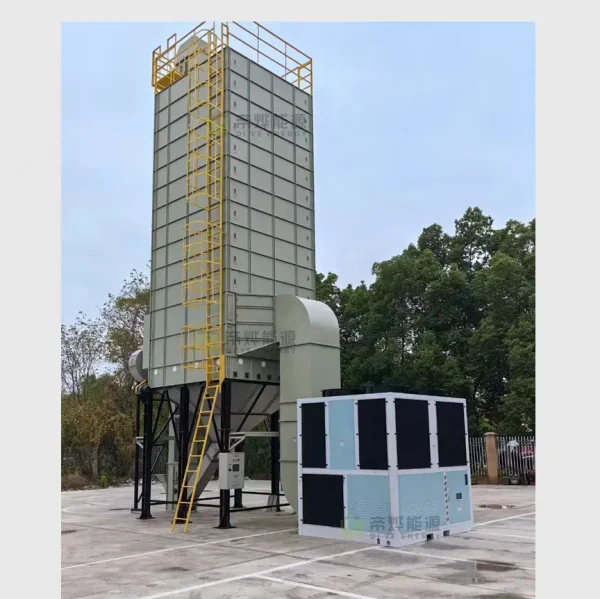

Paddy Moisture Removal Drying Tower

Paddy Moisture Removal Drying Tower

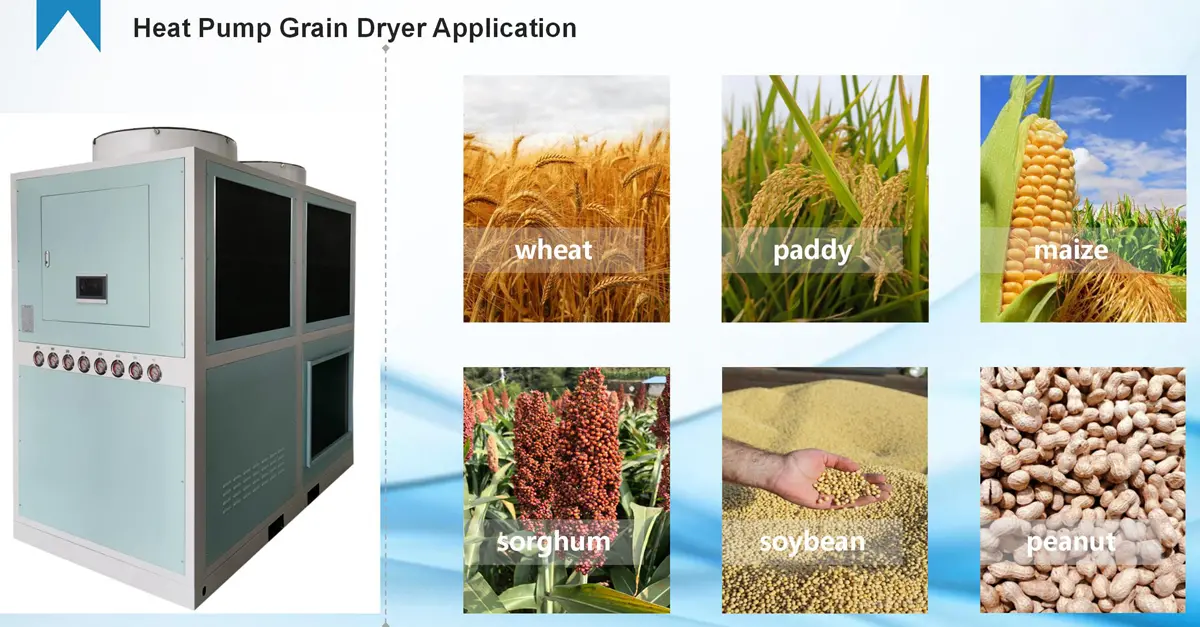

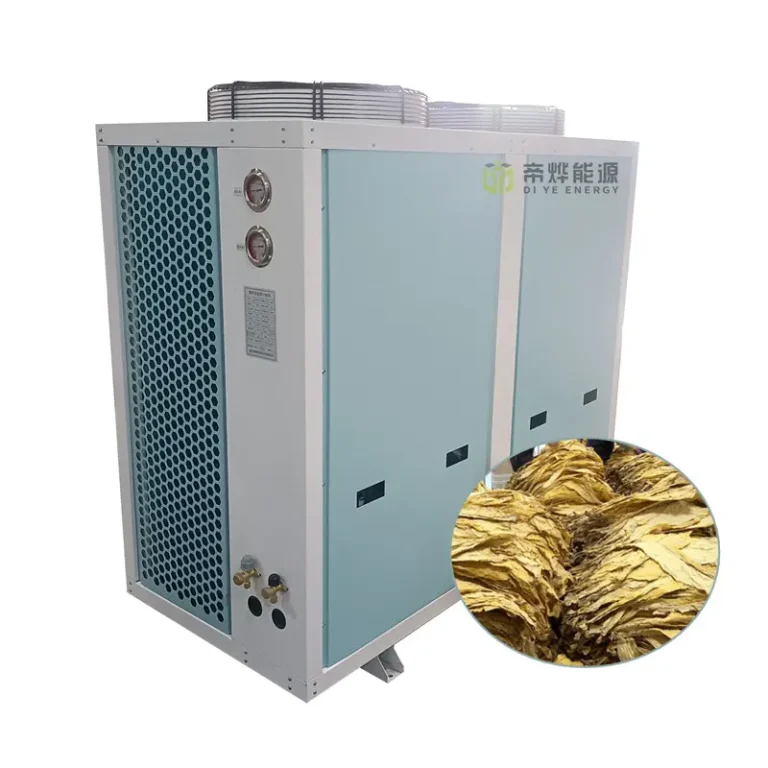

Heat pump grain dryers are used for drying agricultural products: corn,maize,wheat,peanuts,oil seed,etc.

The drying process is to remove humidity and prevent the products from fungi or mildew,which provides the possibility of longer time storage.

Share to:

Paddy Moisture Removal Drying Tower,Grain Drying House

Heat pump grain dryers are used for drying agricultural products: corn,maize,wheat,peanuts,oil seed,etc.

The drying process is to remove humidity and prevent the products from fungi or mildew,which provides the possibility of longer time storage.

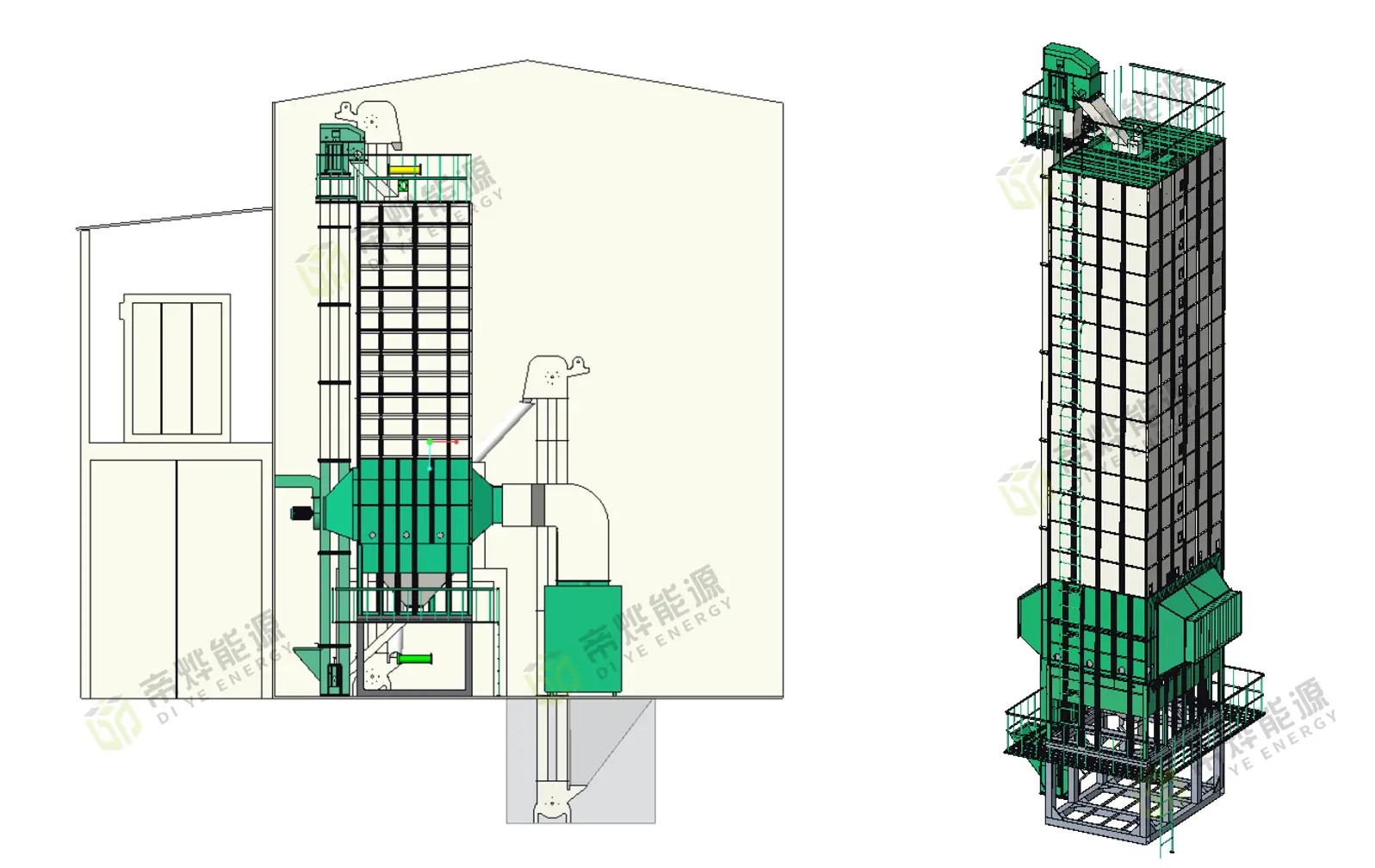

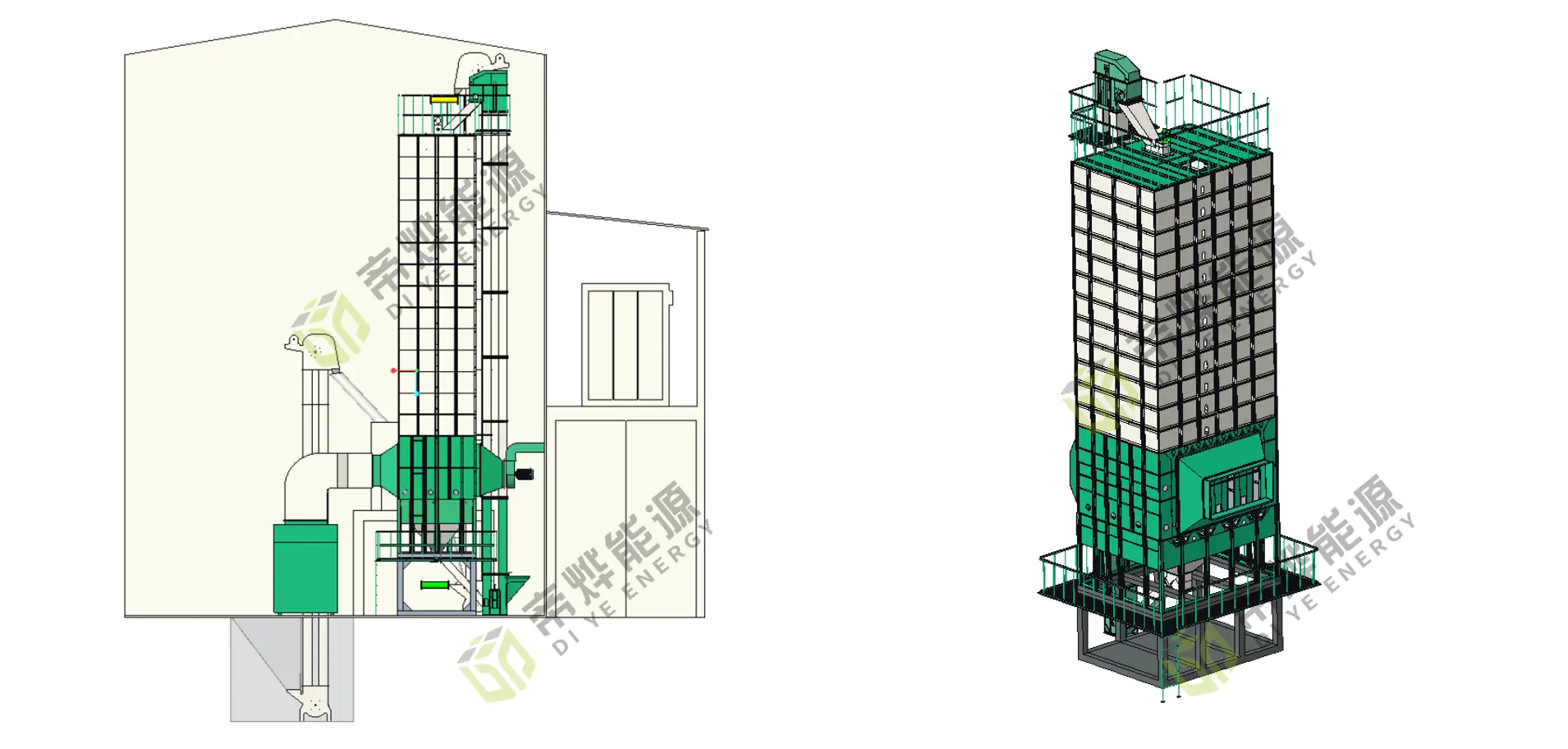

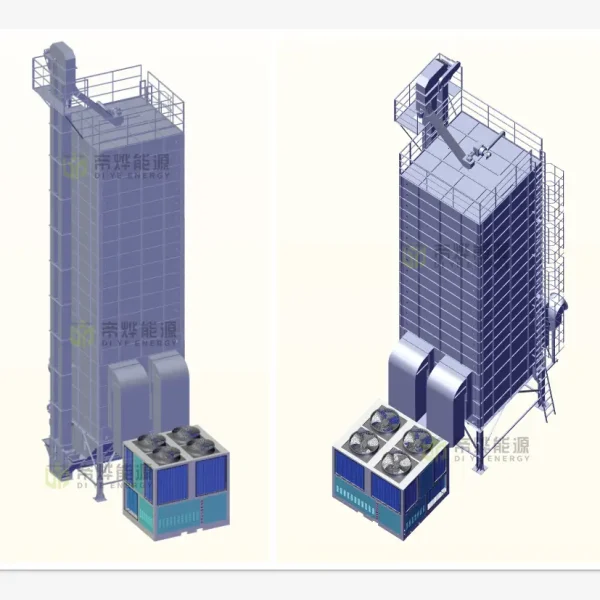

· The grain dryer equipment has a simple structure; Small volume after dismantling,easy for transportation and movement.

· Equipped with online moisture meter,automatic moisture control to prevent over-drying and weight loss.

· Automatic temperature control system:the hot air temperature and air volume can be adjusted during drying process automatically to ensure the top drying quality.

· Highly automated operation with microcomputer control to reduce labor and improve working efficiency.

· Increased drying area and the drying speed is accelerated.

· Variety of heat sources can be applied,including biomass,fuel,gas,coal,etc.

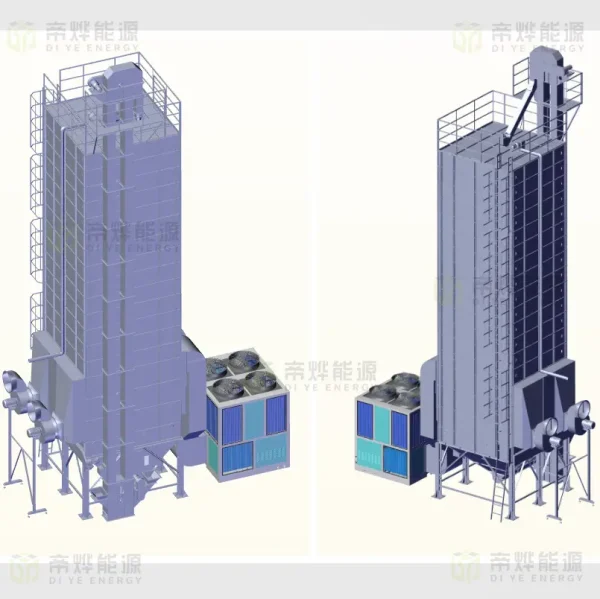

–The crack ratio during the grain process is not only related to the temperature of the hot air,but also the moisture content of the hot air. Under the same temperature conditions,the grain crack ratio is lower when the air moisture content is higher. In order to make the crack ratio is less than 5% ,the hot air temperature should be below 40℃. Depending on the type of grain dryers,the temperature of hot air is also different.

–Cross-flow and mixed-flow drying temperature can reach 45℃~60℃ while countercurrent drying should be lower about 40℃;But they can all achieve good drying results. In order to ensure the drying quality and reduce the crack ratio,a lower medium temperature must be used,generally below 50℃.

Rice, wheat, corn, soybeans and other grains;

The grain dryer uses hot air as the drying medium and adopts a cyclic drying process.

The grains are heated evenly and adequately with good drying quality.